"Lighting purchased for overseas tours either gets stuck in customs due to lack of regional certification, fails waterproofing during outdoor performances, or receives no response to after-sales repair requests for half a month!" The frustration of a procurement manager at a multinational performance company echoes the common dilemmas faced by countless B2B buyers in overseas stage lighting procurement. Cross-border procurement inherently involves challenges such as inconsistent international standards and complex scenario requirements. Coupled with issues like unidentifiable manufacturer qualifications and inadequate after-sales support, a simple lighting purchase often becomes a "pitfall-ridden nightmare."

Today, we first dissect the core pain points of overseas stage lighting procurement, then comprehensively analyze how XMLITE addresses them, offering buyers a worry-free and reliable cross-border procurement solution.

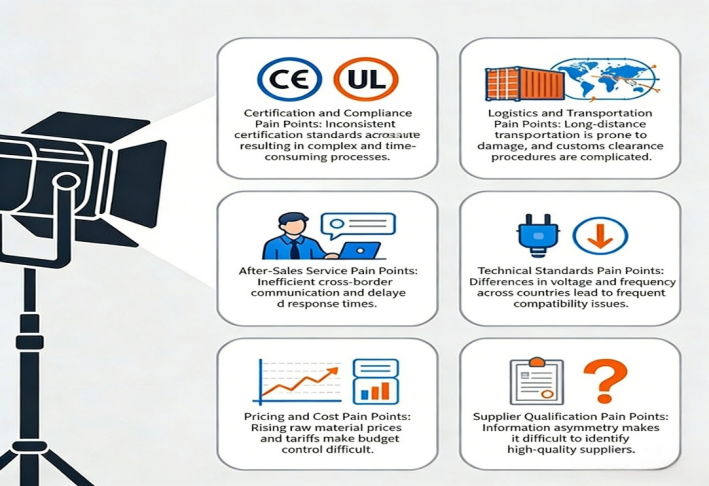

I. Six Core Pain Points in Overseas Stage Lighting Procurement—Have You Encountered Them?

1. Certification Compliance Pain Point: Inconsistent Standards, Difficult Customs Clearance & Market Access

Different regions have vastly varying safety and environmental standards for electrical equipment. International system certifications, regional specific certifications, and industry qualifications are indispensable. If purchased products lack key certifications such as EU CE/RoHS or North American UL, or if certifications are non-compliant, they will not only fail to pass customs clearance but may also face risks like market bans and safety penalties, directly delaying performance preparations.

2. Scenario Adaptation Pain Point: Diverse Needs, "One-Size-Fits-All" Products Fall Short

Overseas performances cover diverse scenarios including large-scale concerts, theaters, outdoor light shows, and banquets, each with drastically different lighting performance requirements: outdoor events demand waterproof and dustproof capabilities, theaters require high color rendering, concerts need high brightness and long projection distance, and banquets call for cost-effective and easy-to-adjust lighting. However, most manufacturers lack targeted product portfolios, and their "universal" lighting fails to meet specific scenario needs, resulting in subpar performance effects.

3. Technical Performance Pain Point: Difficulty Balancing Effect & Cost

Buyers hope for lighting with high luminous flux, low light decay, and precise dimming, while also controlling operational costs such as cross-border transportation and long-term maintenance. Yet many products either fail to meet performance standards—insufficient brightness, distorted color rendering, rapid light decay—or have unreasonable designs—bulky bodies leading to soaring transportation costs, or simple structures unable to adapt to complex environments. Achieving the dual goals of "artistic effect + cost control" remains a challenge.

4. After-Sales Service Pain Point: Difficult Cross-Border Maintenance, No Risk Mitigation

Cross-border procurement involves long transportation cycles and high on-site maintenance difficulty. Once lighting malfunctions occur, buyers often face the dilemma of "no one to complain to and hard-to-find spare parts." Most manufacturers offer short warranty periods and limited coverage, lacking professional overseas technical support teams and global service networks. Failure to promptly repair faulty equipment may directly cause performance disruptions and substantial economic losses.

5. Manufacturer Identification Pain Point: Qualification Fraud, Severe Intermediary Markups

During cross-border procurement, buyers struggle to conduct on-site inspections of manufacturer strength, making them vulnerable to "three-no manufacturers" (no qualifications, no production lines, no after-sales service) or intermediaries. Some suppliers forge certification documents and exaggerate production capacity but lack their own production lines; intermediaries add multiple layers of markups, raising procurement costs while failing to provide direct technical support and after-sales guarantees, leading to buck-passing when problems arise.

6. Cross-Border Inspection Pain Point: Time-Space Constraints, High Cost of Verifying Strength

Overseas on-site inspections of manufacturers require significant time, manpower, and financial resources, which most buyers cannot afford. This prevents buyers from intuitively confirming manufacturers' production scale, R&D capabilities, and product quality, forcing them to rely on written materials—easily misled by false promotions and ending up with products that fall short of expectations.

II. XMLITE’s Comprehensive Solutions—Precisely Addressing Six Procurement Pain Points

Based on years of cross-border service experience and core capabilities, XMLITE has developed an end-to-end solution covering "compliance, scenarios, technology, after-sales, qualifications, and inspections," helping buyers completely avoid pitfalls.

1. Compliance Certification Advantage: Full-Chain Certification, Unblocking Overseas Market Access

XMLITE holds a complete compliance certification system, covering the entire process from production to market access, thoroughly resolving customs clearance and access challenges:

· Comprehensive International System Certifications:

ISO 9001:2015 Quality Management System Certification (ensuring standardized production and stable quality), ISO 14001:2015 Environmental Management System Certification + OHSAS 18001:2007 Occupational Health and Safety Management System Certification (meeting overseas core requirements for suppliers' standardized operations);

· No Regional Certification Barriers:

Complete CE and RoHS certifications, directly accessing the EU and Southeast Asian markets that recognize these standards, avoiding customs clearance delays;

· Strong Industry Qualifications:

Recognized as a High-Tech Enterprise, with multiple core patents and software copyrights. Its R&D capabilities are officially certified, meeting high-end market demands for technological innovation.

2. Full-Scenario Adaptation Advantage: Customized Solutions for Large Venues to Small Events

Rejecting the "one-size-fits-all" approach, XMLITE has created tailored product combinations for four core scenarios, precisely matching diverse performance needs:

· Large-Scale Concerts/Sports Venues:

C10 Profile + 260W Beam Light + LED Par Liaght. The C10 Profile (1000W/50,000lm+) supports long-distance projection of 70-80 meters, with a lightweight 35kg design reducing transportation and installation costs; the 260W Beam Light features a 0-3.8° beam angle and 16-bit precise control, paired with LED Par Light to create stunning visual effects;

· Theaters/Broadcasting Studios:

C8 Profile+ High CRI Par Light. The C8 Profile (800W/32,000lm) has a CRI≥95, accurately restoring skin tones and scene details, with a lightweight 29.5kg design for easy installation; the High CRI Par Light offers 0-100% flicker-free linear dimming, meeting recording requirements;

· Outdoor Performances:

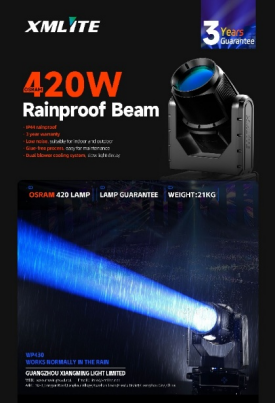

WP430 Waterproof Light + IP65 Par Light. The WP430 Waterproof Beam Light holds an IP65 protection rating, with 13500lm high brightness and a lightweight 21.7kg design, adapting to harsh environments such as rain and sand; the IP65 Waterproof Par Light provides large-area coloring and strong outdoor durability;

· Banquets/Small Events:

295W Beam Light + LED Par Light. The 295W Beam Light is compact and portable, while the LED Par Light supports multi-color switching. Both offer high cost-effectiveness, easy debugging, fast delivery, low energy consumption, and low maintenance, suitable for weddings, business dinners, and other scenarios.

3. Core Technical Advantage: Balancing Effect & Cost for Worry-Free Long-Term Operation

With technological innovation at its core, XMLITE optimizes both "artistic effect and operational cost," resolving the pain point of balancing performance and cost:

· Top-Tier Core Performance:

The C10 Profile delivers high luminous flux for long-distance projection; the C8 Profile offers CRI≥95 and delicate dimming; all products feature low light decay, significantly extending service life and reducing maintenance costs;

· Innovative Structural Design:

Lightweight body designs effectively reduce cross-border transportation and on-site installation costs; high-protection products such as the WP430 Waterproof Beam Light and IP65 Par Light expand scenario applicability; lamps are easy to operate, simplifying usage processes;

· Strong R&D Capabilities:

A professional R&D team of 15 engineers, with 80% of products independently developed. Boasting multiple technological innovation patents, the company has strong product iteration capabilities to quickly respond to personalized needs of overseas performances.

4. After-Sales Support Advantage: Global Coverage, Worry-Free Cross-Border Procurement

XMLITE has built an industry-leading after-sales service system, providing a solid safety net for cross-border procurement:

· Generous Warranty Policy:

Pioneering a "three-year after-sales service" and "light source quality guarantee" policy—far exceeding industry averages—demonstrating absolute confidence in product quality;

· Extensive Service Network:

Technical service centers in over 30 domestic cities, with products exported to more than 70 countries worldwide. Providing timely technical guidance and on-site maintenance support for overseas buyers;

· Efficient Spare Parts Supply:

A comprehensive spare parts supply system ensures rapid delivery of spare parts during cross-border transportation, preventing performance disruptions due to equipment failures.

5. Legitimate Manufacturer Endorsement Advantage: Verifiable Qualifications, Rejecting Intermediaries & Fraud

XMLITE fully meets the five core standards of legitimate stage lighting manufacturers, avoiding procurement risks from the source:

· Fully Verifiable Qualifications:

Providing electronic copies of complete certifications (ISO 9001:2015, ISO 14001:2015, OHSAS 18001:2007, CE, RoHS, etc.) for online verification, ensuring full compliance;

· Visible Production Strength:

A 25,000-square-meter owned production base, standardized assembly lines, and precision testing equipment. A stable team of over 120 employees guarantees production capacity, eliminating delivery delays;

· Verifiable R&D Capabilities:

A 15-engineer team + multiple patents. Core products such as the C10/C8 Profile and WP430 Waterproof Light are independently developed, ensuring reliable technical iteration;

· Traceable Cooperation Cases:

Publicly sharing cooperation information with CCTV, large-scale live-action performances, and projects in over 50 overseas countries. Providing practical application cases of scenario-specific lamps for verification;

· Implementable Customization Services:

Leveraging live-action performance customization experience, supporting scenario-specific customization and OEM/ODM personalized adjustments to meet diverse procurement needs.

6. Convenient Online Factory Audit Advantage: Low-Cost Verification, Visible Strength

XMLITE innovatively offers online factory audit services, breaking time-space barriers for cross-border inspections and enabling buyers to verify manufacturer strength at low cost:

· Intuitive Production Strength:

Real-time live broadcasts of the 25,000-square-meter production base, covering aging test workshops, assembly lines, and precision testing equipment. Clearly demonstrating standardized production processes of products such as the C10 Profile and 260W Beam Light;

· On-Site R&D & Technology Verification:

Professional engineers provide on-site explanations and demonstrate key performance testing processes (e.g., luminous flux, waterproofing), intuitively showcasing lighting effects;

· Authentic Compliance Verification:

Providing electronic verification of certification documents, patent files, and customer cases, offering strong support for customs clearance and procurement decisions;

· Precise Communication on Custom Needs:

One-on-one real-time consultations with professional teams. Directly discussing customization capabilities, delivery cycles, and after-sales guarantees for personalized needs such as concert transportation cost control and outdoor protection upgrades.

III. Conclusion: Choose XMLITE, Avoid 99% of Cross-Border Procurement Pitfalls

The core challenge of overseas stage lighting procurement lies in the "mismatch between pain points and solutions." Starting from buyers' actual needs, XMLITE unblocks market access through compliance certifications, matches diverse needs with full-scenario products, balances effect and cost with core technologies, mitigates risks with comprehensive after-sales support, avoids traps with legitimate qualifications, and reduces inspection costs with online factory audits—comprehensively addressing six core pain points in one stop.

To help buyers fully master cross-border procurement skills, XMLITE has compiled the Practical Guide to Cross-Border Procurement of Overseas Stage Lighting, covering core content such as certification interpretation, scenario-specific selection guidelines, manufacturer identification skills, and after-sales support key points.

Click the link below, fill out the form to download the guide for free, and obtain detailed solutions for XMLITE’s full product line. Whether you are preparing for large-scale international concerts, theater upgrades, or small-event lighting procurement,XMLITE 's professional team will provide one-on-one customized services, making overseas stage lighting procurement more efficient, reliable, and worry-free!

VR

VR 中文

中文 ENGLISH

ENGLISH